Current Status of Digital Complete Dentures Technology

Digital complete dentures technology has revolutionized the field of prosthodontics. It enables dental professionals to fabricate customized dentures using computer-aided design and computer-aided manufacturing (CAD/CAM) techniques. Here, we will discuss the current status of digital complete denture technology.

Digital Scanning Techniques

Digital scanning techniques are an essential part of digital complete denture technology. These techniques include intraoral scanning and extraoral scanning. Intraoral scanning involves the use of an intraoral scanner to capture the patient’s dental arches, which are then used to design the dentures. Extraoral scanning involves the use of a facial scanner to capture the patient’s facial features, such as the shape of their face, lips, and skin color.

CAD/CAM Design

Once the digital scanning is completed, the data is transferred to the CAD/CAM software for designing the dentures. The software allows dental professionals to design dentures that are customized to meet the unique needs of the patient. The software also enables them to adjust the size, shape, and color of the teeth to match the patient’s facial features.

3D Printing

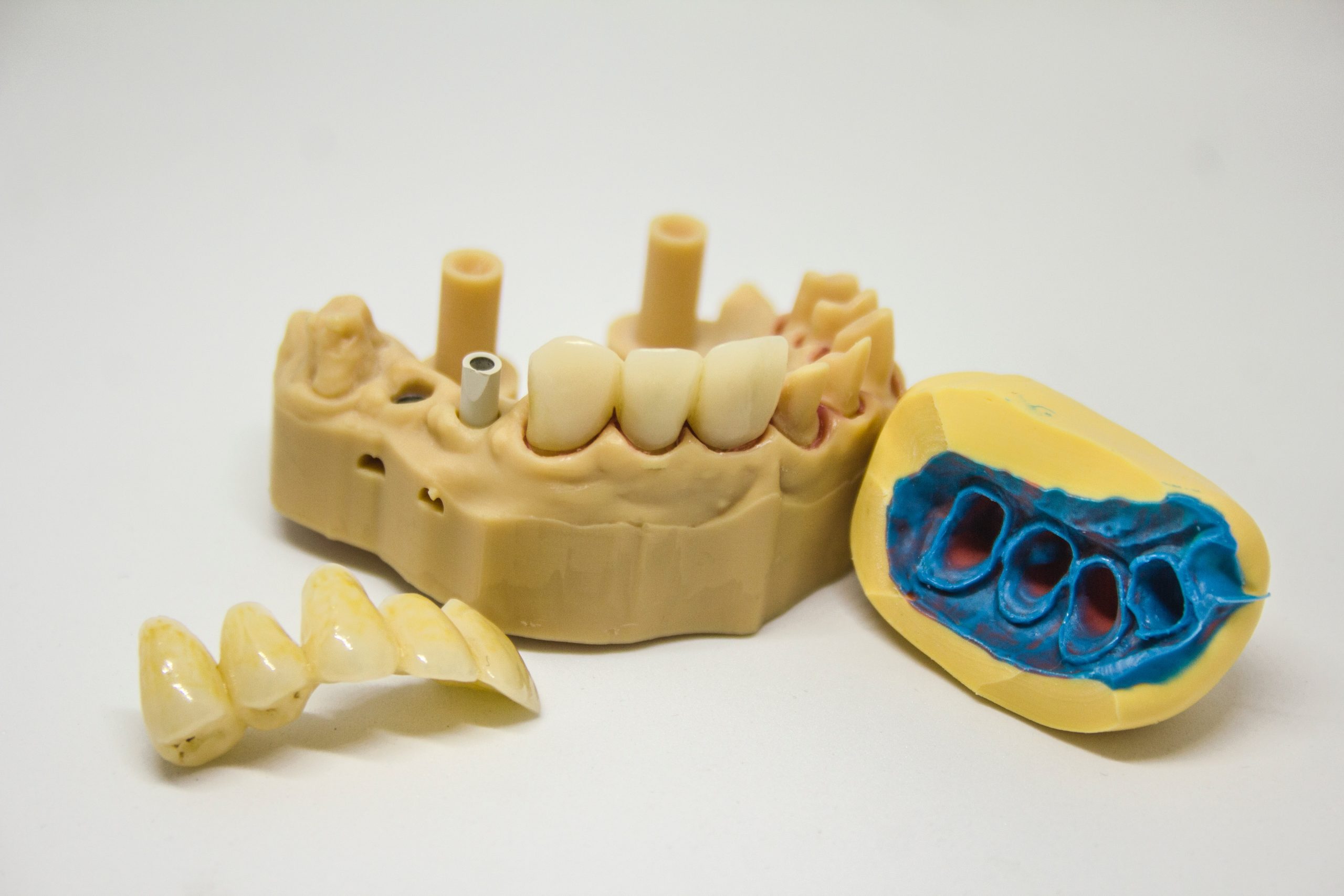

After the denture is designed, the data is sent to a 3D printer, which uses digital data to produce the denture. 3D printing is a fast and efficient way of manufacturing dentures. It allows dental professionals to produce dentures with high accuracy and precision. 3D printing also reduces the amount of waste generated during the manufacturing process.

Advantages of Digital Complete Dentures

Digital complete denture technology offers several advantages over traditional denture manufacturing techniques. Some of these advantages include:

1)Better fit: Digital scanning and CAD/CAM design allow for a more accurate fit of the denture, reducing the likelihood of discomfort or slippage.

2)Time-saving: The digital manufacturing process is much faster than traditional denture manufacturing techniques, reducing the time required for fabrication.

3)Customization: Digital technology allows for customized dentures that are tailored to the patient’s specific needs, improving the overall aesthetic and functional outcome.

4)Reduced waste: 3D printing reduces the amount of waste generated during the manufacturing process, making it more environmentally friendly.

Challenges

Despite the many advantages of digital complete denture technology, there are some challenges associated with its implementation. These include:

1)High initial cost: The cost of digital equipment and software can be high, making it difficult for some dental practices to adopt the technology.

2)Learning curve: The use of digital technology requires a significant amount of training and experience, which can be challenging for some dental professionals.

3)Limited availability: Digital technology is not yet widely available, and many dental practices may not have access to the necessary equipment and software.

Conclusion

Digital complete denture technology has the potential to revolutionize the field of prosthodontics. It offers several advantages over traditional denture manufacturing techniques, including better fit, time-saving, customization, and reduced waste. However, there are also some challenges associated with its implementation, including high initial cost, a learning curve, and limited availability. Despite these challenges, digital complete denture technology is an exciting development that has the potential to improve patient outcomes and make dental practices more efficient and sustainable.